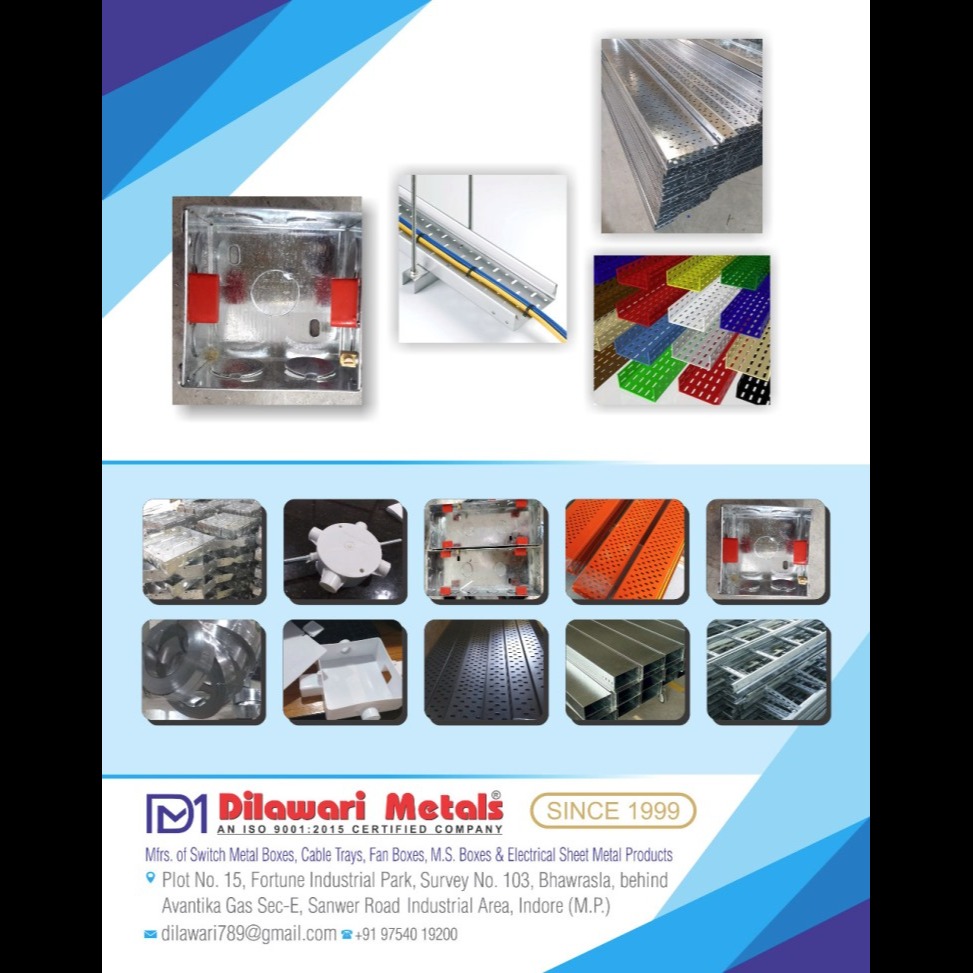

When it comes to electrical installations, one question always arises: how do you manage, protect, and organize a large number of cables safely and efficiently? The answer lies in a tried-and-tested product – the Perforated Cable Tray. In this comprehensive blog, we’ll explore everything you need to know about perforated cable trays, why they are essential in modern industries, how they compare to other cable management systems, and most importantly, why Dilawari Metals, Indore, is your trusted manufacturer and supplier for high-quality perforated cable trays in Madhya Pradesh and across India. What Is a Perforated Cable Tray and Why Is It Used? A perforated cable tray is a type of cable management system designed with holes (perforations) along its base and sides. These perforations serve multiple purposes: They allow better air circulation around the cables, preventing overheating. They make it easy to secure cables with ties and clamps. They provide access points for cable entry and exit. In short, perforated trays are the perfect blend of strength, ventilation, and convenience – making them one of the most widely used cable support systems in commercial and industrial projects. Why Are Perforated Cable Trays Popular in Indore and Madhya Pradesh? Indore, being one of the fastest-growing industrial and IT hubs of Madhya Pradesh, demands organized electrical systems in factories, offices, data centers, and residential projects. But why are perforated cable trays in particular so popular here? Climate Considerations: Madhya Pradesh experiences hot summers, and proper ventilation for cables is crucial to avoid overheating. Industrial Growth: From manufacturing to IT parks, industries in Indore require reliable cable management systems. Ease of Installation: Perforated cable trays allow quick and efficient installation, saving both time and cost. Durability Needs: With high dust levels in central India, a strong and corrosion-resistant tray is a must. This is where Dilawari Metals plays a key role by providing robust and high-quality perforated trays tailored to local needs. What Are the Key Benefits of Perforated Cable Trays? Let’s dive into the advantages that make perforated trays the preferred choice for engineers, contractors, and builders: Efficient Airflow – Prevents cable damage due to overheating. Easy Cable Maintenance – Cables can be easily inspected, replaced, or rerouted. Strong Load-Bearing Capacity – Suitable for both light-duty and heavy-duty cables. Corrosion Resistance – Available in GI (Galvanized Iron), Powder-Coated Steel, and Stainless Steel options. Flexibility in Design – Comes with bends, tees, reducers, and elbows for versatile layouts. Cost-Effective – Long-lasting, reducing the need for frequent replacements. What Materials and Finishes Are Available for Perforated Cable Trays? At Dilawari Metals, Indore, we manufacture perforated trays in different finishes to match your project requirements: GI Perforated Cable Trays – Corrosion-resistant and affordable. Powder-Coated Perforated Cable Trays – Enhanced durability with an aesthetic finish. Hot-Dip Galvanized Perforated Trays – Best for outdoor applications with maximum weather resistance. Stainless Steel Perforated Cable Trays – Ideal for environments requiring hygiene, like food, pharma, and chemical industries. How Do Perforated Cable Trays Compare to Ladder Trays and Raceways? You might be wondering: why should I choose perforated trays over ladder trays or raceways? Perforated vs. Ladder Trays: Ladder trays are excellent for heavy cables over long spans, but perforated trays are more versatile and suitable for a wider range of applications. Perforated vs. Raceways: Raceways completely enclose the cables, but they can lead to overheating. Perforated trays provide ventilation and accessibility. So, if you need a balance of support, ventilation, and accessibility, perforated trays are the perfect choice. Where Are Perforated Cable Trays Commonly Used in Indore? In Indore and across Madhya Pradesh, perforated trays find applications in: IT Parks & Data Centers – To manage complex cable networks. Manufacturing Units & Factories – For reliable power distribution. Commercial Complexes & Malls – To ensure organized wiring systems. Hospitals & Pharma Units – For hygienic and safe electrical management. Residential Projects – Increasingly used in high-rise apartments for neat wiring solutions. Why Choose Dilawari Metals as Your Perforated Cable Tray Manufacturer in Indore? With so many manufacturers available, you might ask: why should I choose Dilawari Metals? Here’s why: Local Expertise in Indore: Understanding the specific requirements of Madhya Pradesh industries. Custom Manufacturing: Trays made to exact sizes, widths, and thicknesses as per client needs. High-Quality Raw Materials: Only premium steel and GI sheets are used. Latest Technology: Precision punching and cutting for accurate

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.dilawarimetals.in/latest-update/when-it-comes-to-electrical-installations-one-question-always-arises-how-do-you-manage-protect-a/1214

When it comes to electrical installations, one question always arises: how do you manage, protect, a...

2025-08-23T06:52:38

When it comes to electrical installations, one question always arises: how do you manage, protect, and organize a large number of cables safely and efficiently? The answer lies in a tried-and-tested product – the Perforated Cable Tray. In this comprehensive blog, we’ll explore everything you need to know about perforated cable trays, why they are essential in modern industries, how they compare to other cable management systems, and most importantly, why Dilawari Metals, Indore, is your trusted manufacturer and supplier for high-quality perforated cable trays in Madhya Pradesh and across India. What Is a Perforated Cable Tray and Why Is It Used? A perforated cable tray is a type of cable management system designed with holes (perforations) along its base and sides. These perforations serve multiple purposes: They allow better air circulation around the cables, preventing overheating. They make it easy to secure cables with ties and clamps. They provide access points for cable entry and exit. In short, perforated trays are the perfect blend of strength, ventilation, and convenience – making them one of the most widely used cable support systems in commercial and industrial projects. Why Are Perforated Cable Trays Popular in Indore and Madhya Pradesh? Indore, being one of the fastest-growing industrial and IT hubs of Madhya Pradesh, demands organized electrical systems in factories, offices, data centers, and residential projects. But why are perforated cable trays in particular so popular here? Climate Considerations: Madhya Pradesh experiences hot summers, and proper ventilation for cables is crucial to avoid overheating. Industrial Growth: From manufacturing to IT parks, industries in Indore require reliable cable management systems. Ease of Installation: Perforated cable trays allow quick and efficient installation, saving both time and cost. Durability Needs: With high dust levels in central India, a strong and corrosion-resistant tray is a must. This is where Dilawari Metals plays a key role by providing robust and high-quality perforated trays tailored to local needs. What Are the Key Benefits of Perforated Cable Trays? Let’s dive into the advantages that make perforated trays the preferred choice for engineers, contractors, and builders: Efficient Airflow – Prevents cable damage due to overheating. Easy Cable Maintenance – Cables can be easily inspected, replaced, or rerouted. Strong Load-Bearing Capacity – Suitable for both light-duty and heavy-duty cables. Corrosion Resistance – Available in GI (Galvanized Iron), Powder-Coated Steel, and Stainless Steel options. Flexibility in Design – Comes with bends, tees, reducers, and elbows for versatile layouts. Cost-Effective – Long-lasting, reducing the need for frequent replacements. What Materials and Finishes Are Available for Perforated Cable Trays? At Dilawari Metals, Indore, we manufacture perforated trays in different finishes to match your project requirements: GI Perforated Cable Trays – Corrosion-resistant and affordable. Powder-Coated Perforated Cable Trays – Enhanced durability with an aesthetic finish. Hot-Dip Galvanized Perforated Trays – Best for outdoor applications with maximum weather resistance. Stainless Steel Perforated Cable Trays – Ideal for environments requiring hygiene, like food, pharma, and chemical industries. How Do Perforated Cable Trays Compare to Ladder Trays and Raceways? You might be wondering: why should I choose perforated trays over ladder trays or raceways? Perforated vs. Ladder Trays: Ladder trays are excellent for heavy cables over long spans, but perforated trays are more versatile and suitable for a wider range of applications. Perforated vs. Raceways: Raceways completely enclose the cables, but they can lead to overheating. Perforated trays provide ventilation and accessibility. So, if you need a balance of support, ventilation, and accessibility, perforated trays are the perfect choice. Where Are Perforated Cable Trays Commonly Used in Indore? In Indore and across Madhya Pradesh, perforated trays find applications in: IT Parks & Data Centers – To manage complex cable networks. Manufacturing Units & Factories – For reliable power distribution. Commercial Complexes & Malls – To ensure organized wiring systems. Hospitals & Pharma Units – For hygienic and safe electrical management. Residential Projects – Increasingly used in high-rise apartments for neat wiring solutions. Why Choose Dilawari Metals as Your Perforated Cable Tray Manufacturer in Indore? With so many manufacturers available, you might ask: why should I choose Dilawari Metals? Here’s why: Local Expertise in Indore: Understanding the specific requirements of Madhya Pradesh industries. Custom Manufacturing: Trays made to exact sizes, widths, and thicknesses as per client needs. High-Quality Raw Materials: Only premium steel and GI sheets are used. Latest Technology: Precision punching and cutting for accurate

2025-08-23T06:52:38

Keywords

- Durable perforated cable trays for industries

- Cable tray installation for factories

- Custom-sized cable trays manufacturer

- Corrosion-resistant perforated trays

- Reliable cable organization Indore

- Ventilated cable support solutions

- Galvanized steel cable trays India

- Heat resistant perforated cable trays

- Industrial electrical cable management systems

- Perforated cable trays manufacturer Madhya Pradesh

Submit Your Enquiry