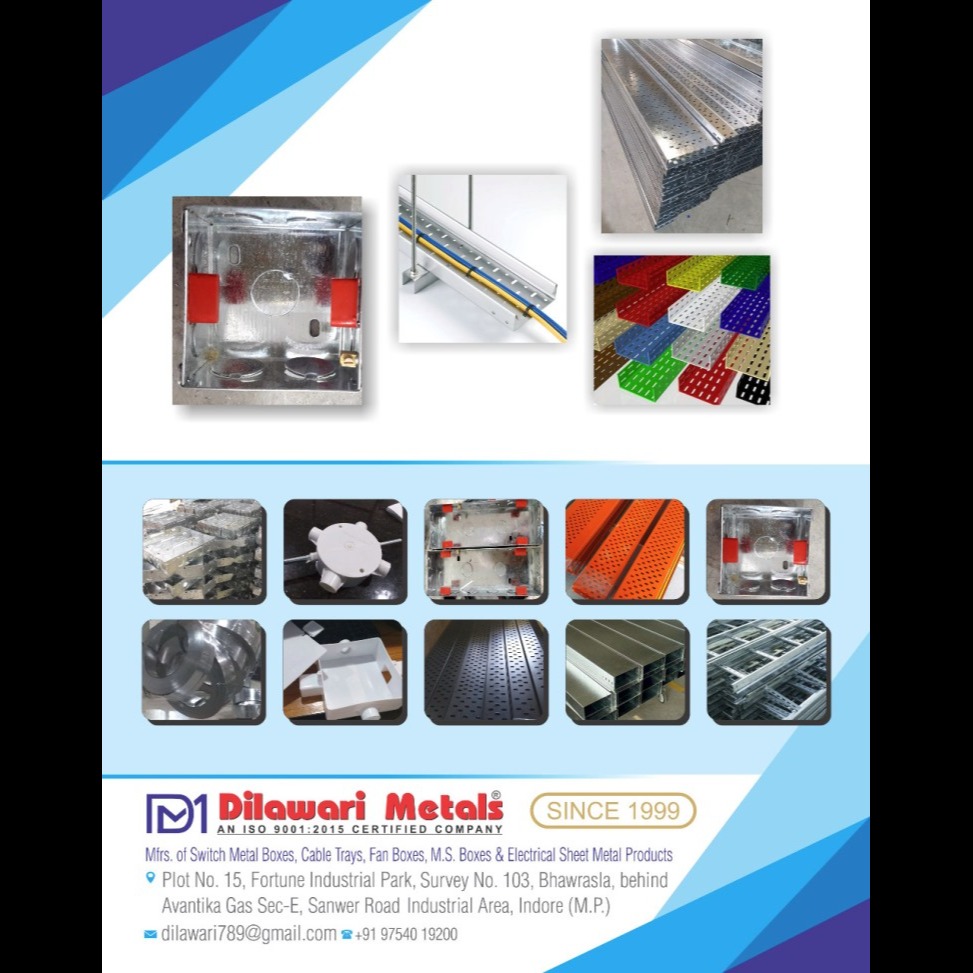

Have you been searching for a trusted cable tray manufacturer in Indore? Or perhaps you need a reliable supplier for high-quality cable trays in Madhya Pradesh? Look no further—Dilawari Metals, based in Indore (since 1999), is your go-to name for durable, efficient, and customized cable management systems. But what makes Dilawari Metals stand out in a competitive market of cable tray manufacturers in Indore and beyond? Let’s explore. Local strength & presence in Indore, MP Operating from Plot No. 15, Sector E, Sanwer Road, Indore, Madhya Pradesh, Dilawari Metals has strong roots in the region. Their familiarity with local market demands, local project standards, and timely delivery logistics across Indore (and adjacent districts) gives them an edge. Decades of experience & expertise Since its establishment in 1999, Dilawari Metals has honed its manufacturing, design, and servicing capabilities. Over 25 years of operations has allowed them to build trust, processes, and a wide portfolio—including cable trays and modular metal boxes. Broad cable tray portfolio Dilawari Metals offers a rich variety of cable trays: hot dip galvanized trays, wire mesh trays, perforated cable trays, heavy duty trays, mild steel trays, stainless steel trays, and powder‑coated custom trays. This diversity ensures clients can select the right tray type for specific environments and load classes. Customization, quality & certifications The company emphasizes customized trays made to specification, rigorous quality control, and material selection to ensure durability. For corrosive or harsh environments, they offer stainless steel or powder-coated finishes. For clients in Indore and the wider Madhya Pradesh region, this reduces freight times and costs significantly. What Is a Cable Tray — And Why Does It Matter? Before diving into types and use cases, let’s clarify: What is a cable tray? A cable tray is a structural support system used to route, support, and protect insulated electrical cables, control wiring, instrumentation lines, or communication cables. It helps organize cable runs, maintain safety clearances, allow ventilation (dissipating heat), and facilitate future cable additions or removals. Why use a cable tray instead of conduit or open wiring? Better heat dissipation & reduced overheating A well‑ventilated tray (e.g. perforated or ladder design) allows heat from cables to escape, reducing degradation risk. Flexibility & scalability Cable trays allow you to add or replace cables easily without dismantling rigid conduit runs. Cost efficiency For large cable bundles or long runs, trays tend to be faster to install and maintain. Safety and organization A tidy layout reduces tangle, accidental damage, and helps during troubleshooting. Where are cable trays used? Cable trays are widely used across industries: manufacturing plants, data centers, power substations, telecom & IT infrastructure, hospitals, commercial buildings, and large residential complexes. In Indore’s growing industrial zones and commercial projects, cable management is critical. What Cable Tray Types Does Dilawari Metals Offer? Dilawari Metals offers many types suited for different loads, environments, and project requirements. Here’s a breakdown you can use for your projects: 1. Ladder Type Cable Tray Open-rung ladder structure (side rails + rungs) Ideal for heavy power cables, long spans, large bundles Maximum ventilation and easy cable placement Frequently used in industrial plants, large factories, and high-load projects 2. Perforated Cable Tray Solid bottom plate with uniformly spaced holes Provides partial ventilation, while protecting cable bottoms Suitable for moderate cable counts or control wiring 3. Wire Mesh (Cable Basket) Tray Mesh design using welded wire or strip form Lightweight, flexible, quick to install Common in IT data centers, telecom racks, light wiring runs 4. Hot-Dip Galvanized (GI) Cable Tray Galvanized Iron coating for corrosion resistance Suitable for outdoor or humid environments Standard choice for many industrial setups 5. Stainless Steel Cable Tray Offers highest corrosion resistance (for chemical plants, coastal sites, etc.) Longer life under harsh environments 6. Heavy Duty Cable Tray Thicker gauge, reinforced structure Built for heavy trays, or zones with dynamic loads 7. Powder-Coated or Custom Coated Trays Custom finishes over GI or mild steel Suitable when aesthetic or special protec

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.dilawarimetals.in/latest-update/perforated-cable-tray/1240

PERFORATED CABLE TRAY

2025-10-09T05:32:23

Have you been searching for a trusted cable tray manufacturer in Indore? Or perhaps you need a reliable supplier for high-quality cable trays in Madhya Pradesh? Look no further—Dilawari Metals, based in Indore (since 1999), is your go-to name for durable, efficient, and customized cable management systems. But what makes Dilawari Metals stand out in a competitive market of cable tray manufacturers in Indore and beyond? Let’s explore. Local strength & presence in Indore, MP Operating from Plot No. 15, Sector E, Sanwer Road, Indore, Madhya Pradesh, Dilawari Metals has strong roots in the region. Their familiarity with local market demands, local project standards, and timely delivery logistics across Indore (and adjacent districts) gives them an edge. Decades of experience & expertise Since its establishment in 1999, Dilawari Metals has honed its manufacturing, design, and servicing capabilities. Over 25 years of operations has allowed them to build trust, processes, and a wide portfolio—including cable trays and modular metal boxes. Broad cable tray portfolio Dilawari Metals offers a rich variety of cable trays: hot dip galvanized trays, wire mesh trays, perforated cable trays, heavy duty trays, mild steel trays, stainless steel trays, and powder‑coated custom trays. This diversity ensures clients can select the right tray type for specific environments and load classes. Customization, quality & certifications The company emphasizes customized trays made to specification, rigorous quality control, and material selection to ensure durability. For corrosive or harsh environments, they offer stainless steel or powder-coated finishes. For clients in Indore and the wider Madhya Pradesh region, this reduces freight times and costs significantly. What Is a Cable Tray — And Why Does It Matter? Before diving into types and use cases, let’s clarify: What is a cable tray? A cable tray is a structural support system used to route, support, and protect insulated electrical cables, control wiring, instrumentation lines, or communication cables. It helps organize cable runs, maintain safety clearances, allow ventilation (dissipating heat), and facilitate future cable additions or removals. Why use a cable tray instead of conduit or open wiring? Better heat dissipation & reduced overheating A well‑ventilated tray (e.g. perforated or ladder design) allows heat from cables to escape, reducing degradation risk. Flexibility & scalability Cable trays allow you to add or replace cables easily without dismantling rigid conduit runs. Cost efficiency For large cable bundles or long runs, trays tend to be faster to install and maintain. Safety and organization A tidy layout reduces tangle, accidental damage, and helps during troubleshooting. Where are cable trays used? Cable trays are widely used across industries: manufacturing plants, data centers, power substations, telecom & IT infrastructure, hospitals, commercial buildings, and large residential complexes. In Indore’s growing industrial zones and commercial projects, cable management is critical. What Cable Tray Types Does Dilawari Metals Offer? Dilawari Metals offers many types suited for different loads, environments, and project requirements. Here’s a breakdown you can use for your projects: 1. Ladder Type Cable Tray Open-rung ladder structure (side rails + rungs) Ideal for heavy power cables, long spans, large bundles Maximum ventilation and easy cable placement Frequently used in industrial plants, large factories, and high-load projects 2. Perforated Cable Tray Solid bottom plate with uniformly spaced holes Provides partial ventilation, while protecting cable bottoms Suitable for moderate cable counts or control wiring 3. Wire Mesh (Cable Basket) Tray Mesh design using welded wire or strip form Lightweight, flexible, quick to install Common in IT data centers, telecom racks, light wiring runs 4. Hot-Dip Galvanized (GI) Cable Tray Galvanized Iron coating for corrosion resistance Suitable for outdoor or humid environments Standard choice for many industrial setups 5. Stainless Steel Cable Tray Offers highest corrosion resistance (for chemical plants, coastal sites, etc.) Longer life under harsh environments 6. Heavy Duty Cable Tray Thicker gauge, reinforced structure Built for heavy trays, or zones with dynamic loads 7. Powder-Coated or Custom Coated Trays Custom finishes over GI or mild steel Suitable when aesthetic or special protec

2025-10-09T05:32:23

Keywords

- Modular metal cable tray manufacturers Indore

- Industrial cable tray solutions Madhya Pradesh

- Durable powder-coated cable trays Madhya Pradesh

- Wire mesh cable tray manufacturer Indore

- Heavy duty cable trays supplier Madhya Pradesh

- Galvanized iron cable tray manufacturer Indore

- Stainless steel perforated cable trays Madhya Pradesh

- Custom cable management systems Indore

- High-quality cable tray supplier Madhya Pradesh

- Perforated cable tray manufacturer Indore

Submit Your Enquiry