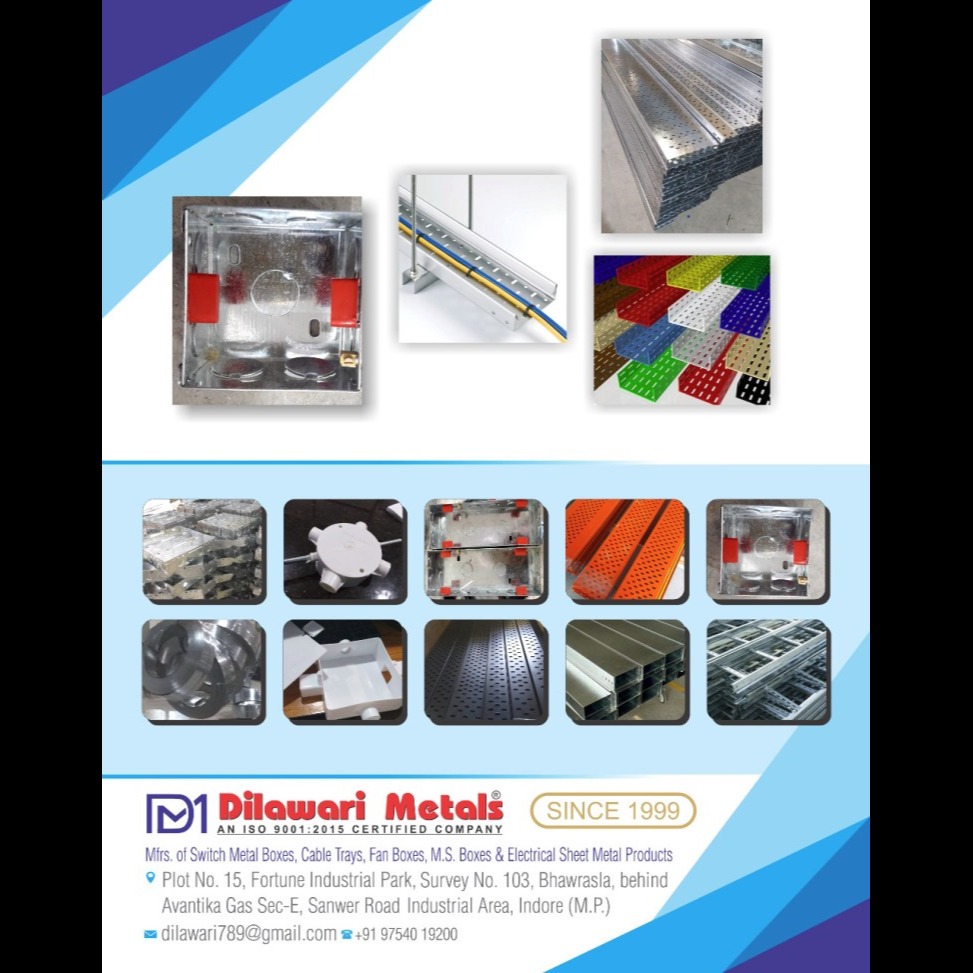

In a rapidly evolving industrial and infrastructure environment, the importance of smart, reliable cable management cannot be overstated. Whether you’re working on a commercial building, manufacturing plant, data centre or multi-storey residential complex, the backbone of your electrical and communication wiring system lies in the quality of your cable support structure. That’s where Dilawari Metals, based in Indore, Madhya Pradesh, stands out as a premier cable tray manufacturer—offering end-to-end solutions that combine durability, precision and cost‐effectiveness. Why Cable Trays Matter in Modern Infrastructure When it comes to electrical systems, power distribution, signal transmission, fiber optics and network cables, they all need a structured, secure pathway to run safely. Cable trays do more than just hold cables: they: Provide a clear, organised routing system for power and communication cables, allowing easy access when adding, changing or maintaining cables. Allow for better ventilation and heat dissipation, reducing risks associated with overheating and ensuring long-term cable performance. Support heavy loads, protect against mechanical stress, vibration and cutting forces — essential in industrial environments. Help minimise fire risk by avoiding cable bunching, facilitating inspection and compliance with safety standards. Offer greater flexibility than traditional conduits for upgrades and retrofits. For contractors, project managers and maintenance teams, choosing the right cable tray system is a critical decision that impacts installation time, maintenance costs, safety and scalability. Introducing Dilawari Metals – Your Cable Management Partner Founded in 1999, Dilawari Metals has built a reputation for engineering excellence, material integrity and project-ready execution. Dilawari Metals +1 Located at Plot No. 15, Fortune Industrial Park, Behind Avantika Gas, Sector E, Sanwer Road, Indore (Madhya Pradesh 452015) Justdial +1 , the company enjoys a strategic presence in Central India, enabling streamlined logistics across Madhya Pradesh and adjacent states. Key credentials: Over two decades of experience in manufacturing cable trays, modular metal boxes and related components. Dilawari Metals +1 A robust manufacturing facility equipped for cutting, forming, galvanizing, welding and finishing to deliver precise and reliable products. Dilawari Metals Verified on platforms like JustDial and TradeIndia, reinforcing its credibility and industry standing. Justdial +1 A strong customer focus, with solutions tailored to project specifications and drawing requirements. As a cable tray manufacturer in Indore, MP, Dilawari Metals is committed to delivering quality, reliability and value — making it the go-to choice for electrical contractors, EPC houses, system integrators and facility managers. Product Portfolio: Cable Trays by Dilawari Metals Dilawari Metals offers a comprehensive range of cable tray systems designed to meet diverse project demands. The choices cater to industrial heavy-duty installations, commercial buildings, data centres, HVAC systems, telecommunication networks and more. Types / Designs Ladder Type Cable Tray: Consists of two side rails with rungs at regular intervals. This design allows excellent ventilation and easy cable laying/maintenance — especially suitable for heavy power cables and industrial plant environments. Dilawari Metals +1 Perforated or Slotted Cable Tray: Features a base plate (and sometimes side rails) with perforations or slots for cable support. Ideal for lighter or medium-load installations, telecom and signal cables, or clean-room style environments. Dilawari Metals +1 Wire Mesh / Basket Tray: Offers maximum flexibility, ease of retrofits, and fitting in tight spaces or where frequent changes happen. (While not explicitly listed in all product pages, typical cable tray manufacturers like Dilawari Metals also cater to retrofit friendly types as part of their portfolio.) Heavy Duty / Industrial Cable Tray: Reinforced structure designed for high load, heavy-duty industrial installations, chemical plants, offshore platforms or outdoor use. The robust engineering and thicker material profiles are key here. Modular & Custom Tray Systems: Custom bends, tees, transitions, couplers, supports and finishes engineered per client drawings or onsite requirements. As noted: “Customized shapes, bends, tees … built to client drawing or site conditions.” Dilawari Metals Materials & Finishes Mild Steel (MS): Economical, workable, suitable for many indoor installations. Pre-Galvanized Steel: Coated sheet steel prior to manufacture, offering better corrosion resistance in mild indoor environments. Hot-Dip Galvanized (HDG): Immersed in molten zinc, offering thick and durable coating—ideal for outdoor, harsh, or corrosive environments. Dilawari Metals Stainless Steel (SS): For highly corrosive or hygienic environments, e.g., chemical plant

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.dilawarimetals.in/latest-update/cable-tray/1255

cable tray

2025-11-06T05:47:57

In a rapidly evolving industrial and infrastructure environment, the importance of smart, reliable cable management cannot be overstated. Whether you’re working on a commercial building, manufacturing plant, data centre or multi-storey residential complex, the backbone of your electrical and communication wiring system lies in the quality of your cable support structure. That’s where Dilawari Metals, based in Indore, Madhya Pradesh, stands out as a premier cable tray manufacturer—offering end-to-end solutions that combine durability, precision and cost‐effectiveness. Why Cable Trays Matter in Modern Infrastructure When it comes to electrical systems, power distribution, signal transmission, fiber optics and network cables, they all need a structured, secure pathway to run safely. Cable trays do more than just hold cables: they: Provide a clear, organised routing system for power and communication cables, allowing easy access when adding, changing or maintaining cables. Allow for better ventilation and heat dissipation, reducing risks associated with overheating and ensuring long-term cable performance. Support heavy loads, protect against mechanical stress, vibration and cutting forces — essential in industrial environments. Help minimise fire risk by avoiding cable bunching, facilitating inspection and compliance with safety standards. Offer greater flexibility than traditional conduits for upgrades and retrofits. For contractors, project managers and maintenance teams, choosing the right cable tray system is a critical decision that impacts installation time, maintenance costs, safety and scalability. Introducing Dilawari Metals – Your Cable Management Partner Founded in 1999, Dilawari Metals has built a reputation for engineering excellence, material integrity and project-ready execution. Dilawari Metals +1 Located at Plot No. 15, Fortune Industrial Park, Behind Avantika Gas, Sector E, Sanwer Road, Indore (Madhya Pradesh 452015) Justdial +1 , the company enjoys a strategic presence in Central India, enabling streamlined logistics across Madhya Pradesh and adjacent states. Key credentials: Over two decades of experience in manufacturing cable trays, modular metal boxes and related components. Dilawari Metals +1 A robust manufacturing facility equipped for cutting, forming, galvanizing, welding and finishing to deliver precise and reliable products. Dilawari Metals Verified on platforms like JustDial and TradeIndia, reinforcing its credibility and industry standing. Justdial +1 A strong customer focus, with solutions tailored to project specifications and drawing requirements. As a cable tray manufacturer in Indore, MP, Dilawari Metals is committed to delivering quality, reliability and value — making it the go-to choice for electrical contractors, EPC houses, system integrators and facility managers. Product Portfolio: Cable Trays by Dilawari Metals Dilawari Metals offers a comprehensive range of cable tray systems designed to meet diverse project demands. The choices cater to industrial heavy-duty installations, commercial buildings, data centres, HVAC systems, telecommunication networks and more. Types / Designs Ladder Type Cable Tray: Consists of two side rails with rungs at regular intervals. This design allows excellent ventilation and easy cable laying/maintenance — especially suitable for heavy power cables and industrial plant environments. Dilawari Metals +1 Perforated or Slotted Cable Tray: Features a base plate (and sometimes side rails) with perforations or slots for cable support. Ideal for lighter or medium-load installations, telecom and signal cables, or clean-room style environments. Dilawari Metals +1 Wire Mesh / Basket Tray: Offers maximum flexibility, ease of retrofits, and fitting in tight spaces or where frequent changes happen. (While not explicitly listed in all product pages, typical cable tray manufacturers like Dilawari Metals also cater to retrofit friendly types as part of their portfolio.) Heavy Duty / Industrial Cable Tray: Reinforced structure designed for high load, heavy-duty industrial installations, chemical plants, offshore platforms or outdoor use. The robust engineering and thicker material profiles are key here. Modular & Custom Tray Systems: Custom bends, tees, transitions, couplers, supports and finishes engineered per client drawings or onsite requirements. As noted: “Customized shapes, bends, tees … built to client drawing or site conditions.” Dilawari Metals Materials & Finishes Mild Steel (MS): Economical, workable, suitable for many indoor installations. Pre-Galvanized Steel: Coated sheet steel prior to manufacture, offering better corrosion resistance in mild indoor environments. Hot-Dip Galvanized (HDG): Immersed in molten zinc, offering thick and durable coating—ideal for outdoor, harsh, or corrosive environments. Dilawari Metals Stainless Steel (SS): For highly corrosive or hygienic environments, e.g., chemical plant

2025-11-06T05:47:57

Keywords

- Marine and outdoor cable trays

- Cost-effective cable tray options

- Electrical cable management solutions

- Reliable cable support structure

- Galvanized steel cable trays MP

- Heat dissipation in cable management

- Perforated and slotted cable trays

- Heavy-duty industrial cable support

- Custom modular cable tray systems

- Industrial cable tray manufacturing Indore

Submit Your Enquiry